Industrial Coatings

Highest quality coating application process

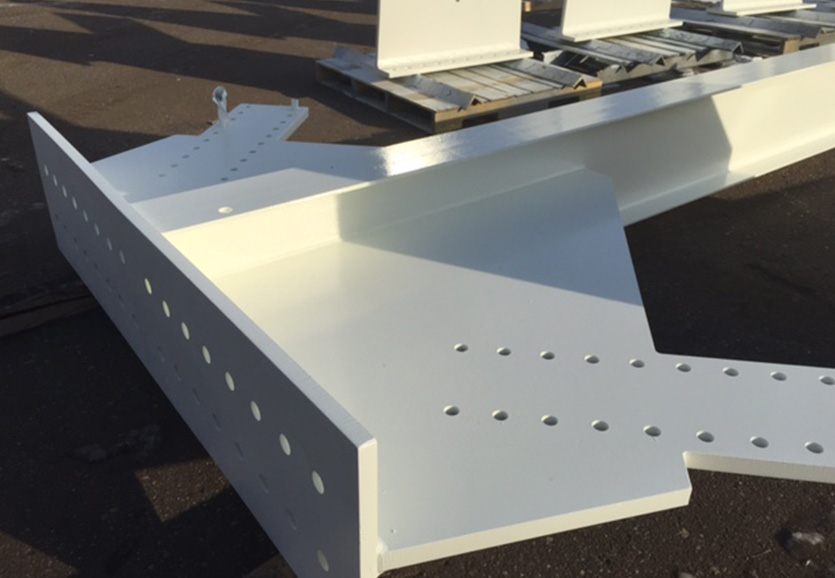

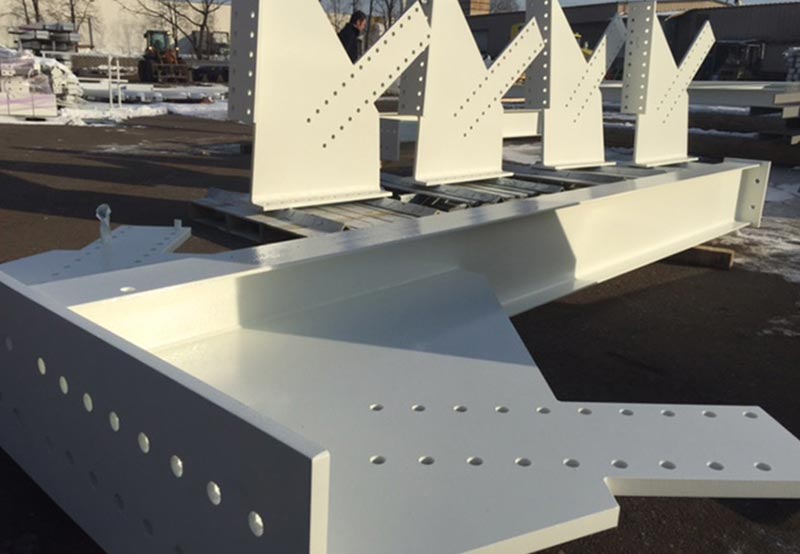

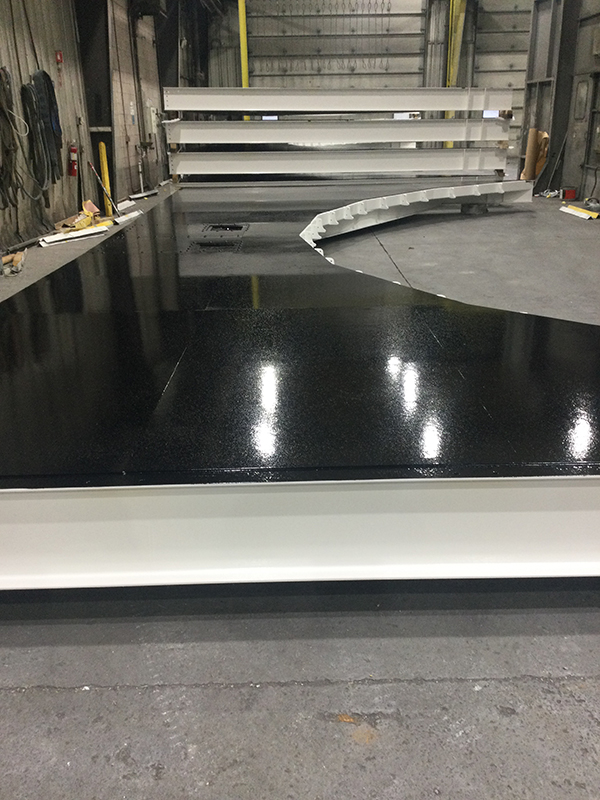

Central Sandblasting is highly specialized in the application of all high-performance coatings. Our team members are trained extensively to ensure on every project we provide the most accurate application per engineering specifications and manufacturer recommendations.

We send our team members to training provided by industry leaders in coating products such as Sherwin Williams, Carboline, Tnemec, and PPG to name a few. This training gives our painters the most up-to-date knowledge and an edge in a rapidly growing industry of new and improved products. We also have an ASTM D4228 certified painter, giving us the ability to work with Nuclear Facility products.

Our quality department is comprised of 2 SSPC Certified Protective Coatings Inspectors. We have a level 1 and level 2 Protective Coatings Inspectors and we are a SSPC QP3 certified facility as well as an approved DOT Contractor in multiple states.

Application Products

- 100% Solid Epoxies

- Polyaspartic

- Anti-Slip Coatings

- Polysiloxanes

- Flouropolymer

- Zinc Rich Epoxy

- Hi-Temp Coatings

- Tank Linings

- Interior Pipe Linings

- Urethane

- Intumescent Fireproofing

- Vinyl Esters

Projects

Certifications

Abrasive Blasting

Specialty Blast Media

The Latest in Blast Booth Technology

Central Sandblasting uses the latest in blasting technologies to provide superior restoration, and surface preparation to every project that enters our facilities. Central Sandblasting is equipped with state of the art blast equipment and booths. Our blast booth is a fully automated, self cleaning, self recycling, steel grit system that recycles out all of the broken down steel grit material in order to ensure that your project receives the proper specification profile requirements based on ASTM/SSPC standards. This system is also faster, cleaner and healthier for our team members.

Central Sandblasting team members are trained and certified in abrasive blasting using all types of blast media including steel shot, steel grit, aluminum oxide, ruby red garnet, black beauty coal slage, glass bead, crushed walnut shells, and fine sand custom mixes to name a few. Other media is available upon request.

SERVICES YOU CAN RELY ON

- Structural steel

- Bar Joists

- Industrial equipment

- Pressurized Tanks

- Paint removal

- Rust removal

- Lead Abatement

- Glass Bead Aluminum

- Stainless Steel

- Interior/Exterior Pipe

- Steel Plate

UTILIZING THE BEST METHODS

- Aluminum Oxide

- Glass Bead

- Soda Blast

- Steel Grit

- Steel Shot

- Walnut Shells

- Ruby Red Garnet

- Black Beauty Coal Slage

- Fine sand custom mixes

.

FACILITIES & EQUIPMENT

Conveniently located in New Brighton, Minnesota, Central Sandblasting’s facilities are truly state-of-the-art. Two paint booths, both equipt with overhead cranes and one 250' continuous rail line, all in a 41,000 sq. ft. shop provide for year round blasting and coating operations. Central Sandblasting is also equipped with two individual blast booths including one that is a fully automated, self cleaning, self recycling, steel grit system capable of handling a variety of blast media and any materials up to 120’ long by 20’ high by 20’ wide in overall size. We also have a pangborn wheelabrator capable of blasting plate up to 8' wide and beams with a 36" flange width and 36" height. We pride ourselves on consistant focus on environmental safety, compliance, and maintenance.

41,000 Square foot shop facility

State-of-the-Art Paint Booths

Environmentally Safe and Compliant